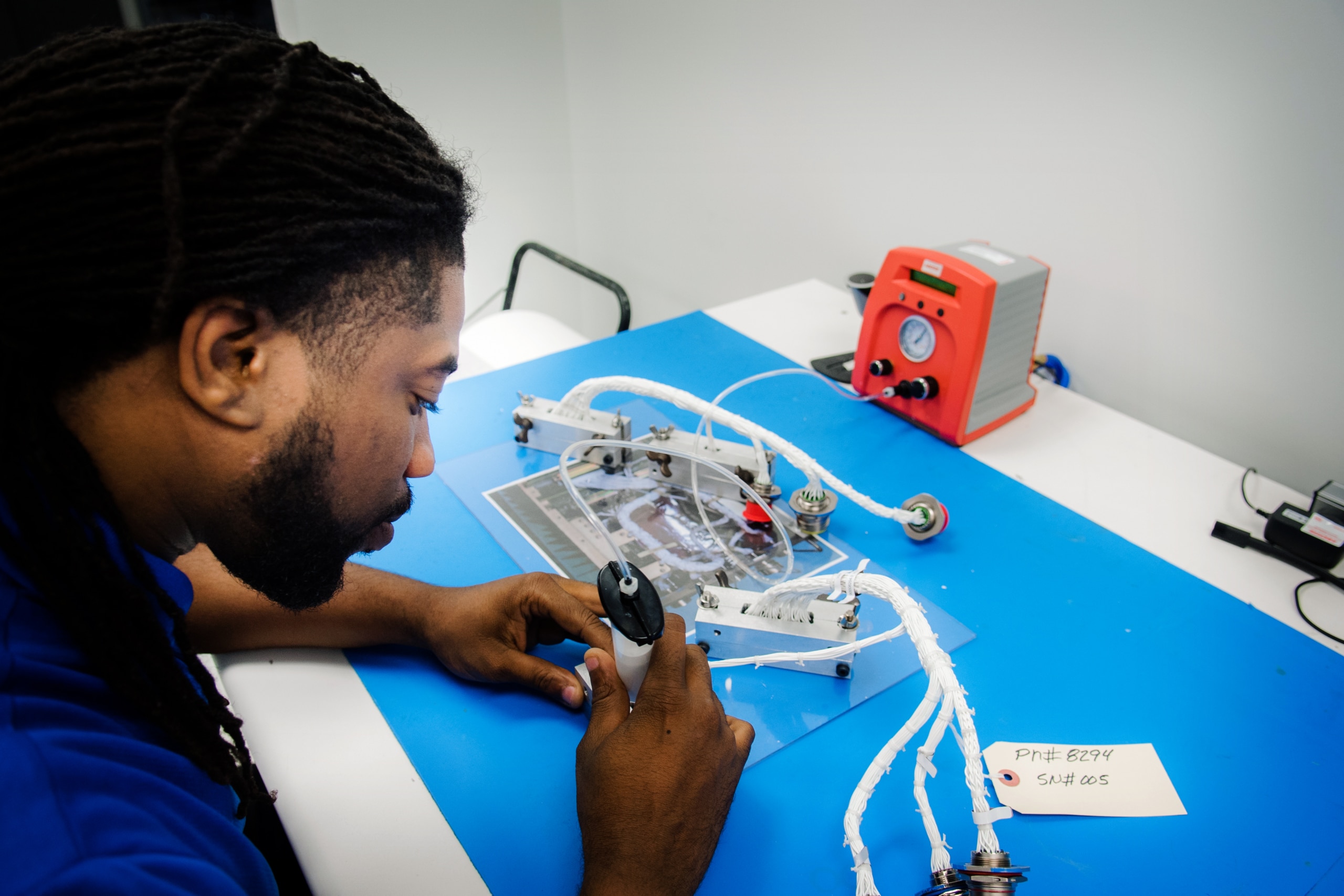

Stark’s Electronics Division has grown from a single EO/IR repair contract to a multitude of assembly, repair, and overhaul programs ranging from EO/IR production and repair of Inertial Navigation Units for military use. Our excellent performance for U.S. military customers speaks to the ability of our highly skilled workforce.

Capabilities

- Electronic manufacturing is performed in a 5,600 square foot Certified Class 100,000 Clean Room (ISO 8) with wi-fi temperature and humidity control.

- ESS Testing includes two Thermotron Chambers capable of cycles from -70°C to 180°C.

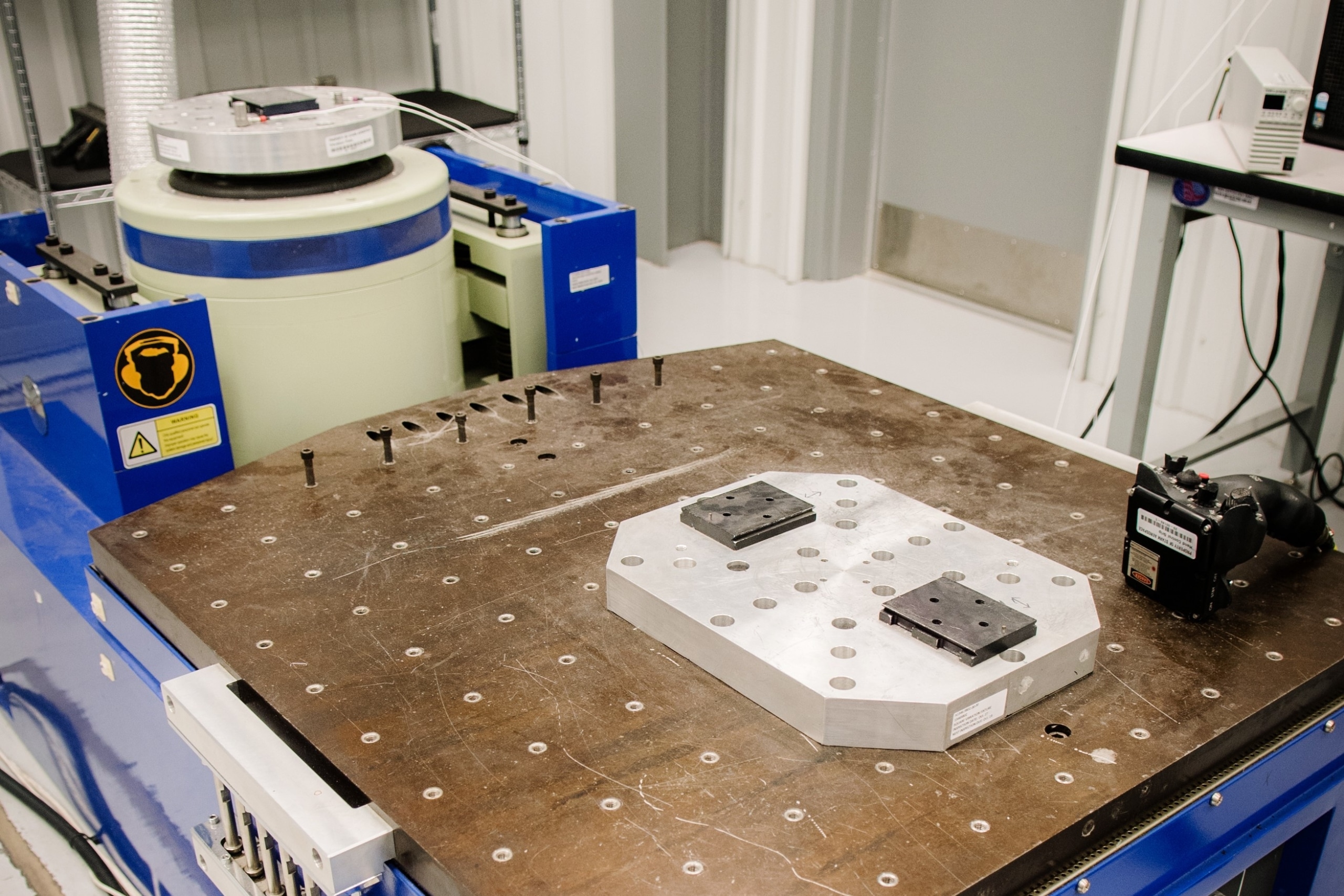

- Vibration Testing is part of the manufacturing verification process. Production units undergo rigorous vibration testing on one of two Dynamic Solutions Vibration Test Systems.

- Line of Sight Calibration for EO/IR Systems. Calibration experts use one of two CI Systems Collimators to certify all units prior to final shipment.

- Ideal Aerosmith Rate Table for gyroscopic calibration and testing.

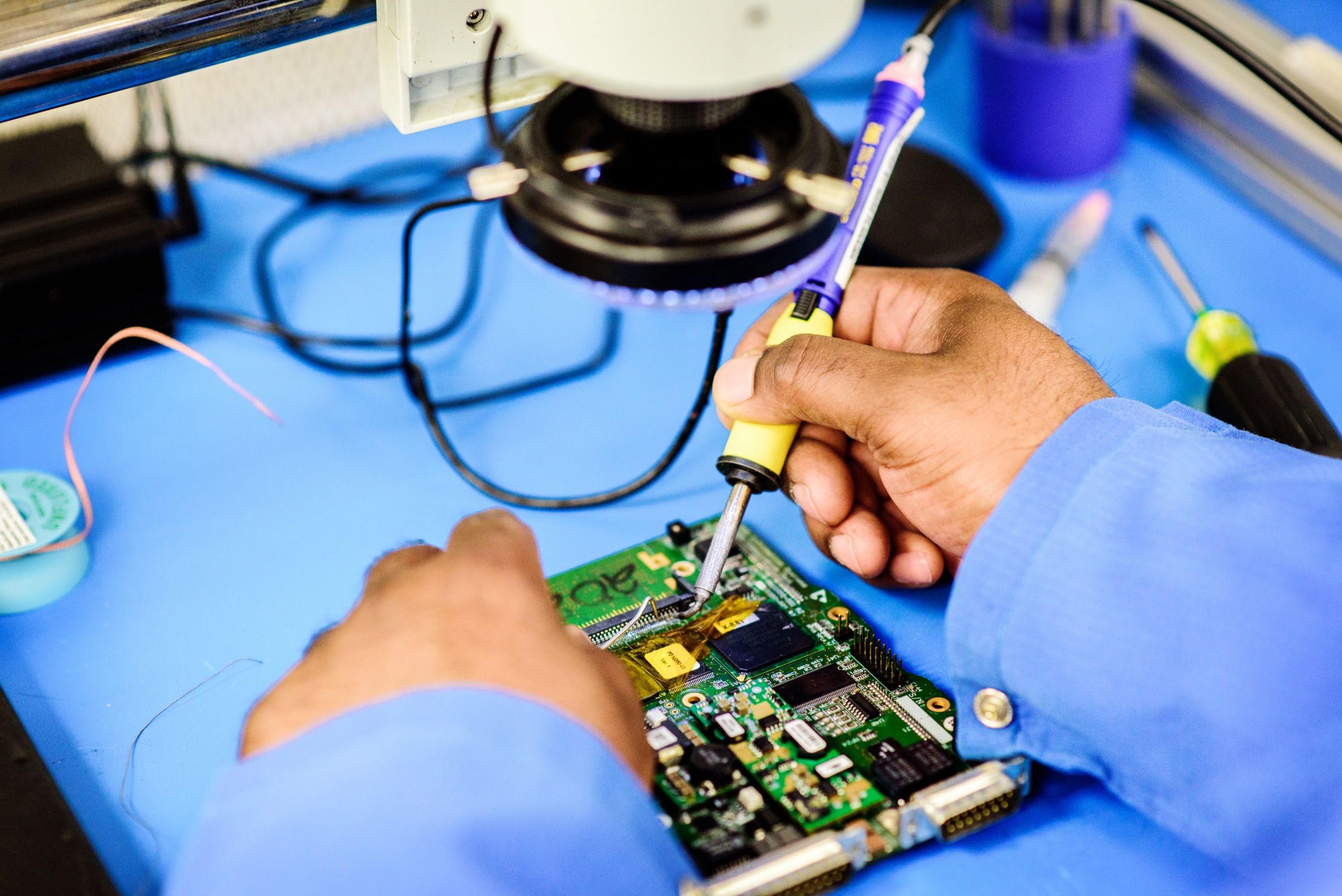

- Certified technicians and internal trainers perform all soldering to the IPC J-STD-001 standard.

- Electronics technicians are certified to the A-610 standard.

POP300/300D

Assembly, repair, overhaul, painting, and calibration of the EO/IR. Since 2009 we have produced and repaired several thousand units for the US Army’s Shadow UAV.

Inertial Navigation System

Inertial Navigation System: Assembly, testing, and calibration of INS for a military end-use under a Foreign Military Financing (FMF) program.

DMU Dynamic Measurement Unit

Assembly, repair, overhaul, and painting of DMUs for military UAVs.

VDTS Video Data Tracker

Repair and overhaul program for military trainers requiring a 4-day turnaround.