Our Missile Systems Division is the result of manufacturing skills and capital equipment acquired over the last 10+ years. Manufacturing processes range from welding and metal assembly to avionics testing and integration. We have a proven track record of on-time delivery and an exceptional quality record.

Capabilities

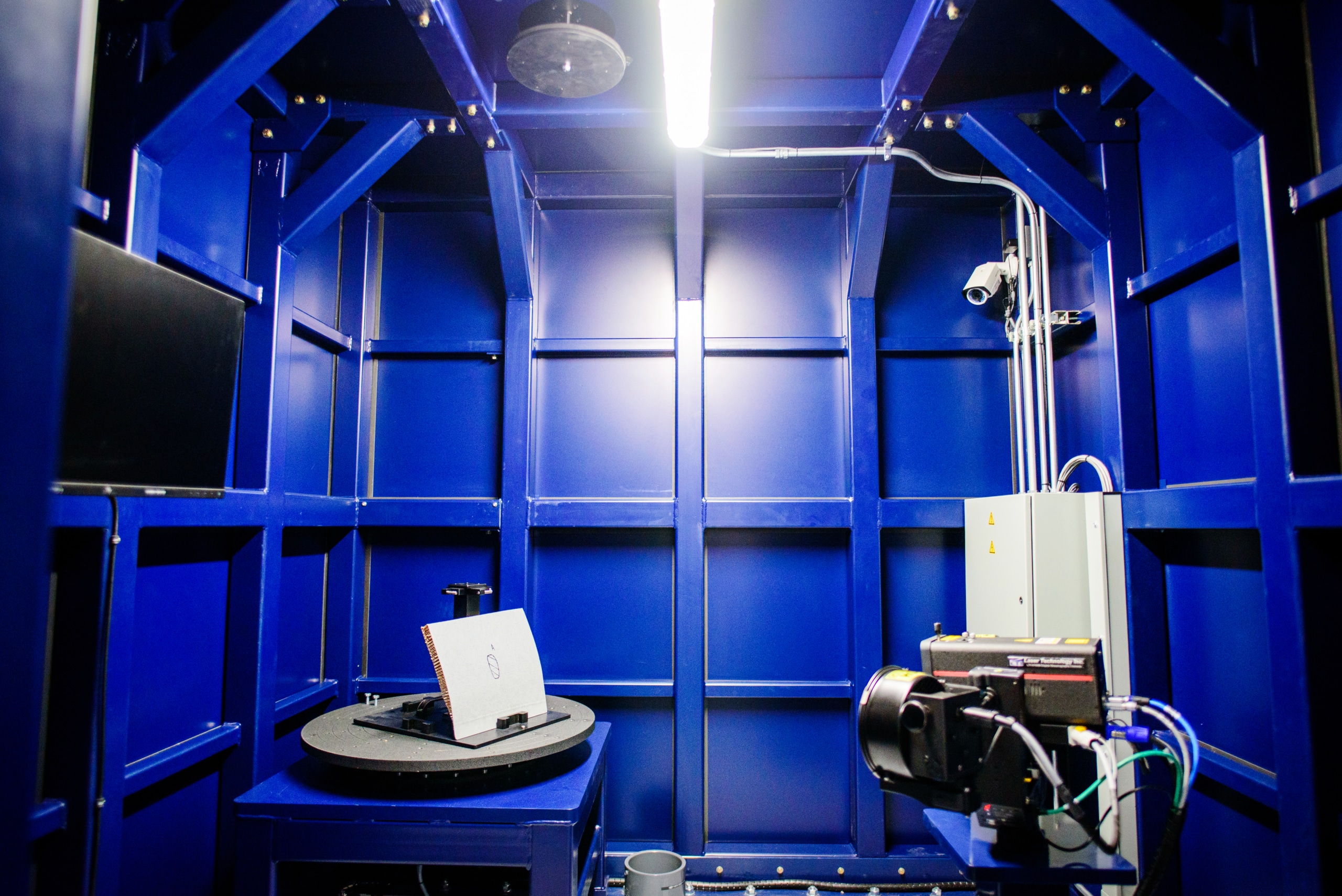

- Laser Shearography is used for any bonded composite material for near-instantaneous void detection as part of the non-destructive testing process.

- 1870 cubic foot sand blast booth for cleaning surfaces during the metallic painting process.

- Thermal Zinc Spraying is a more efficient and consistent alternative to galvanization

- Our highly skilled tig welding team is certified to AWS d1, with a CWI on staff to verify all welding holds to the most stringent quality requirements.

- IPC/WHMA-A-620 Certified technicians to manufacture all wire harnesses to the IPC-620 standard and certified internal trainers for IPC Standards.

- Cutting and Laser Marking Machine increases efficiency by kitting and pre-marking wires, reducing lead time and manufacturing costs.

- Two mobile MK Test Systems perform continuity and insulation testing on 100% of Stark manufactured wire harnesses.